T Cole & Son, in partnership with Ace Fabreeka, provides high-quality solutions that enhance any type of movement, including raising or lowering loads and regulating object feed precisely. Their industry-quality, innovative solutions meet ergonomic and individual requirements, including customizable gas springs.

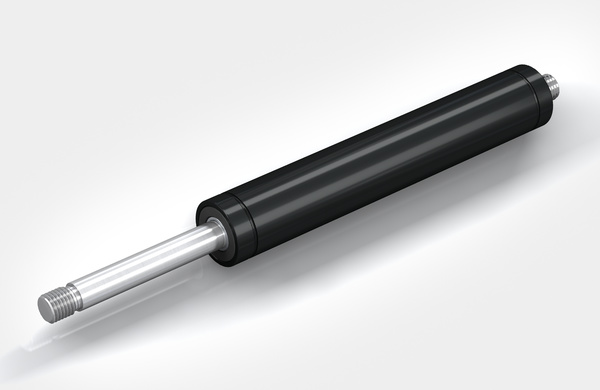

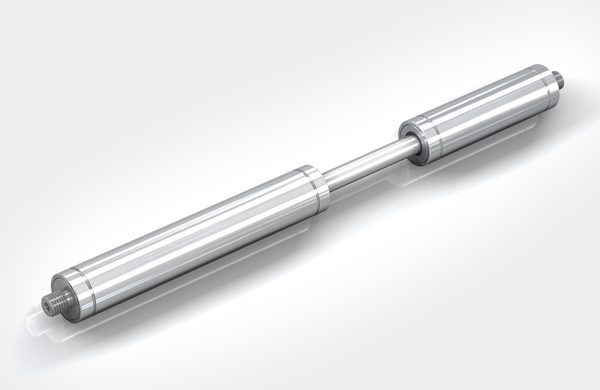

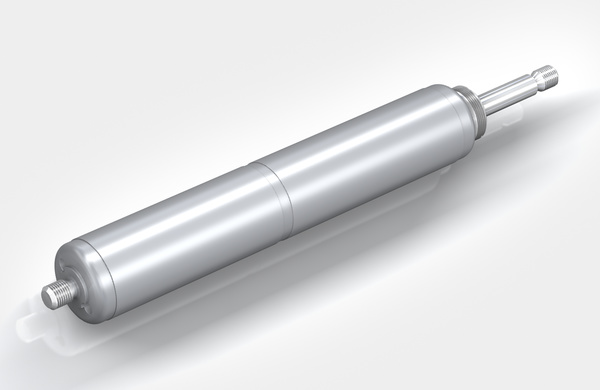

Industrial Gas Springs – Push Type

Anyone who wants to lift or lower loads with control and without excessive strength relies on the industrial gas push type springs from ACE. These maintenance-free, ready-to-install machine elements, which are available from stock, support sheer muscle power and reliably open and hold.

Available with body diameters of 8 to 70 mm and forces from 10 to 13,000 N, ACE gas push type springs are characterised by a huge variety and maximum service life. The first is achieved thanks to the number of available connections and fittings for simple attachment and the latter with high quality design and materials. Whether they are made of steel or stainless steel, these components make any work easier and also make a particularly good impression visually in every branch.

GS-8 to GS-70

Universal and tailor made: ACE industrial gas push type springs of the NEWTONLINE family offer perfect support of muscle power with forces from 10 N to 13,000 N with body diameter of 8 mm to 70 mm.

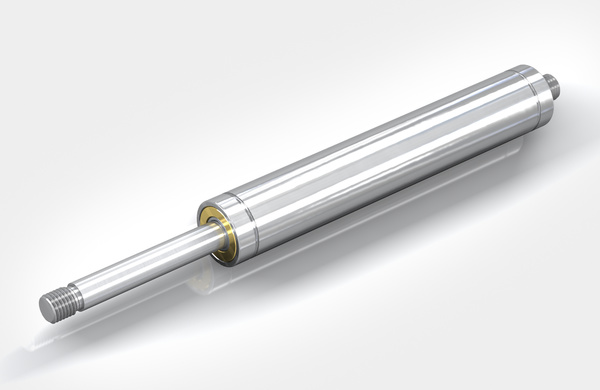

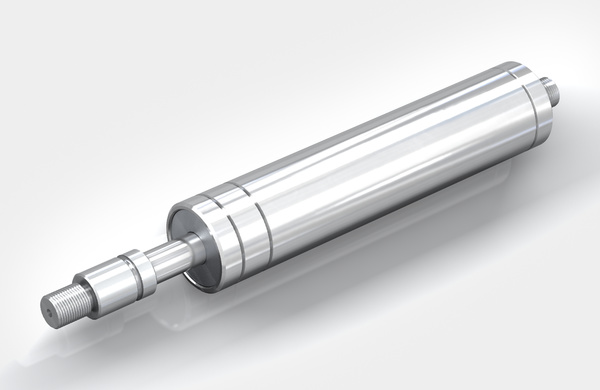

GST-40 Tandem

Cover two differing force ranges: Tandem push type gas springs by ACE are maintenance-free and ready-to-install with two pressure tubes with different extension forces and progression curves.

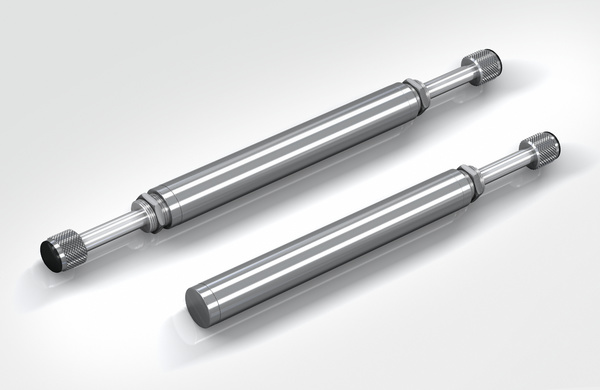

GS-8-V4A to GS-40-VA

Protection against corrosion and superior optics for even more sophisticated requirements: Based on ACE’s industrial gas push type springs GS-8 to 40 made of steel, these models combine all advantages of stainless steel: they look great and are rust free.

GSG-19 to GSG-22

A specially designed gas spring acts as a safety product.

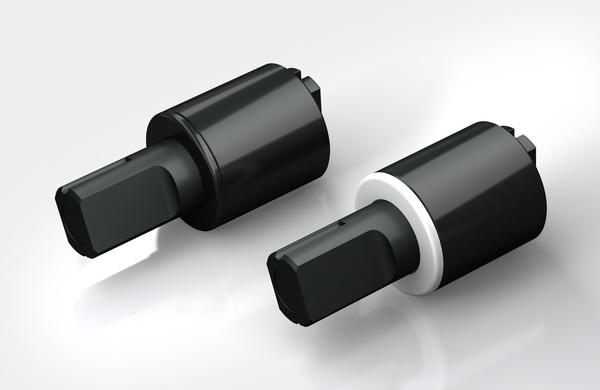

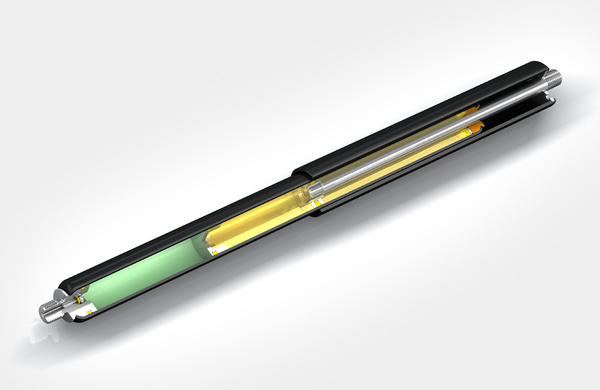

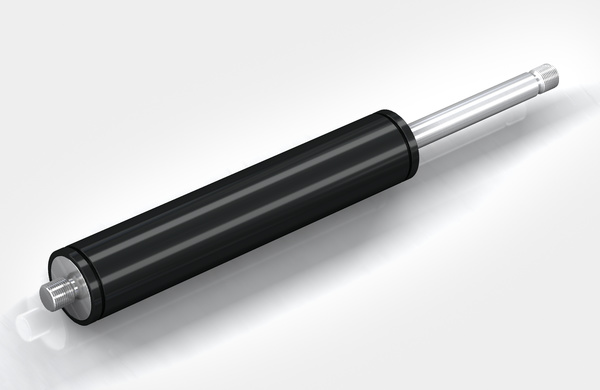

Industrial Gas Springs – Pull Type

If ACE gas push type springs cannot be used due to a lack of space, ACE’s industrial gas pull type springs come into their own. The compact assistants with body diameters of 15 to 40 mm are effective in the direction of traction and work in the opposite way to the principle of gas push type springs.

This means that the gas pressure in the cylinder draws the piston rod in and, when closing a flap for example, supports the manual force with the pressure springs. ACE’s gas pull type springs are also self-contained, maintenance-free machine elements and equipped with a standard valve to individually regulate the gas pressure, whereby they cover forces between 30 and 5,000 N. Any installation position, extensive DIN standardised accessories and various models enable universal use.

Innovations such as diaphragm accumulators, seals, tube-shaped inner pressure chambers and many more make a decisive contribution towards extension of the service life. This means that the effective load range can be extended considerably, which provides users with more scope with respect to the absorber size and utilisation of the machine’s output. ACE offers a wide range of matching accessories for this and all other absorber series. This eliminates internal production of assembly parts, which involves high costs and lots of time.

GZ-15 to GZ-40

The solution to a lack of space: If standard push type gas springs cannot be used due to a lack of space, ACES’ industrial pull type gas springs come into their own.

GZ-15-V4A to GZ-40-VA

Brilliant performance when things become tight: For specific use e.

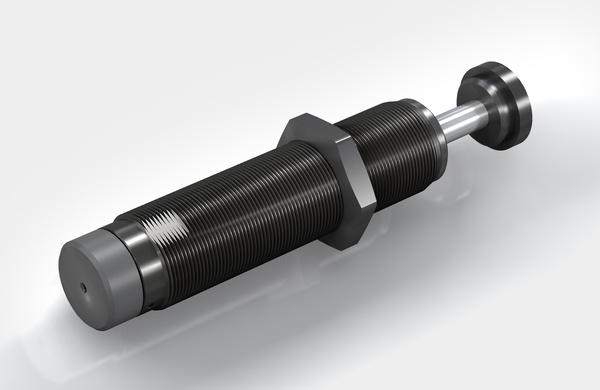

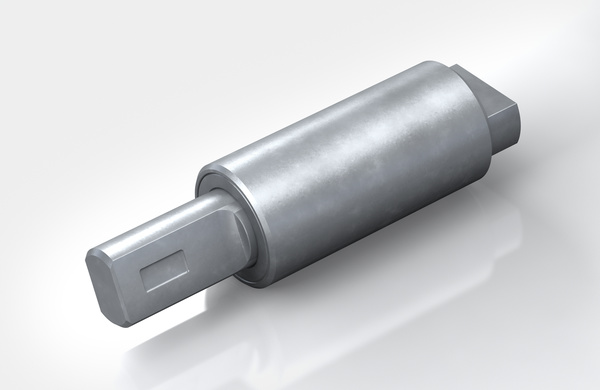

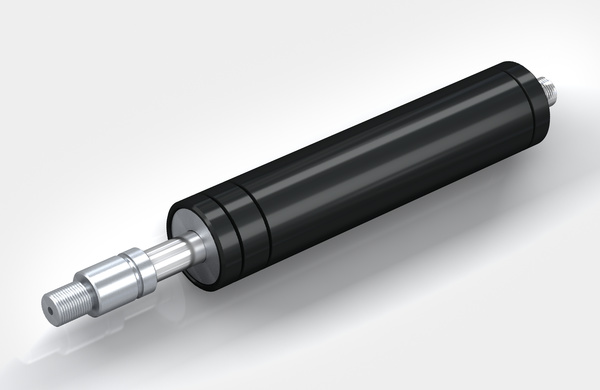

Hydraulic Dampers

The hydraulic dampers are similar in appearance to the ACE industrial gas springs but are adjusted in the end position and work differently to the DVC family with individual speed adjusters for the push and pull direction. This provide users with the maximum flexibility.

Whether used as drive compensation or safety elements, the retraction and extension speed of these ACE solutions can always be precisely set. This means that the speed of movement can be controlled, synchronisation regulated in both directions and pivoting loads can be compensated. Depending on the model, the push and pull forces are between 30 N and 40,000 N. These maintenance-free, ready-to-install products are available in body diameters of 12 mm to 70 mm and in stroke lengths up to 800 mm.

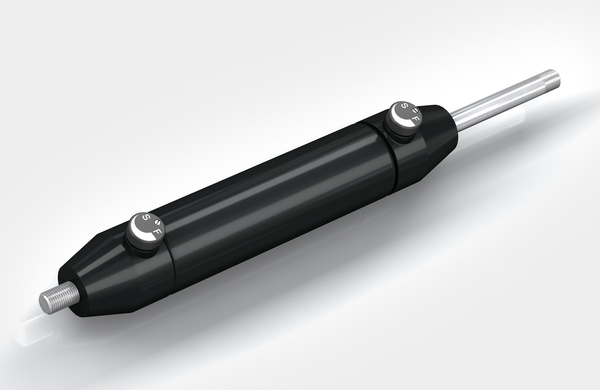

HBS-28 to HBS-70

Damping either in one or both directions: The hydraulic dampers of the product family HBS are made in a slim gas spring design and are compact and high in performance.

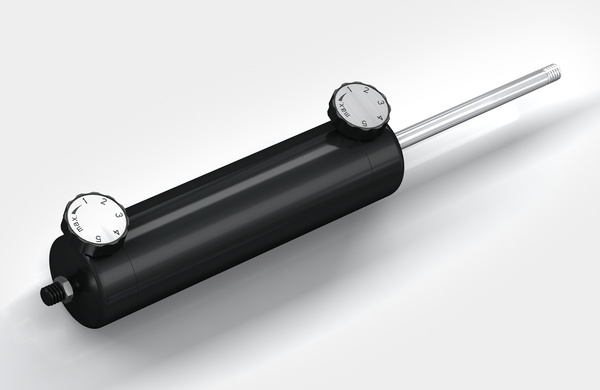

HB-12 to HB-70

High quality and long service life: The hydraulic dampers of the product family HB can also be used as single or double acting brake.

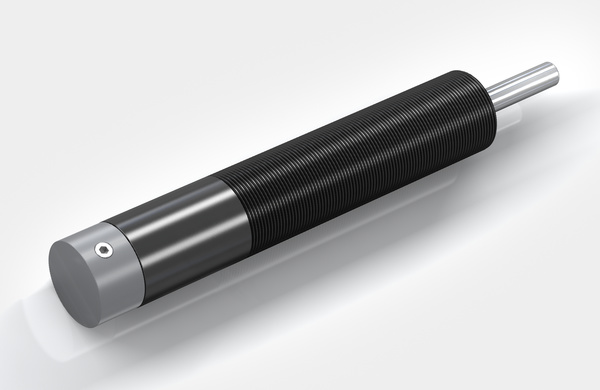

Door Dampers

ACE has high-performance, durable door dampers available to protect elevator doors and other automatically operated or manual door systems from damaging contact. The single or double-sided hydraulic shock absorbers are characterised by their good adjustment capacity and maximum energy absorption between 75 and 190 Nm/Cycle.

The adjustment setting is made for each side independently by turning the retracted piston rod on the knurled head to the required damping force. The possibleimpact velocity for the door can be between 0.1 and 2 m/s, and the dampers manage up to 10 strokes per minute. Typical of ACE: various characteristic curves, special lengths or customised seals available on request.

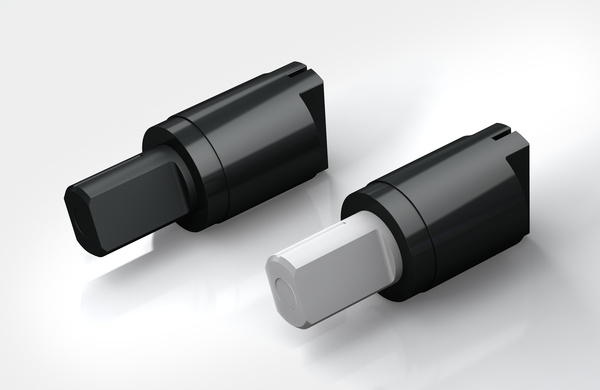

Hydraulic Feed Controls

Hydraulic feed controls from ACE are recommended as the perfect solution e.g. when sawing, cutting, drilling and in order to prevent the stick-slip effect on pneumatic cylinders, amongst others. They can be precisely adjusted and provide speeds from 12 mm/min. with a very low feed force or up to 38 m/min. with a high feed rate.

The maintenance-free, ready-to-install hydraulic feed controls are self-contained, hydraulic elements regulated by a precision throttle. The feed rate is set from the outside by turning the setting adjuster. The tried-and-testing rolling diaphragms used in many ACE shock absorbers also serve as a dynamic sealing element for a hermetic seal as well as volume compensation for the piston rod and resetting element.

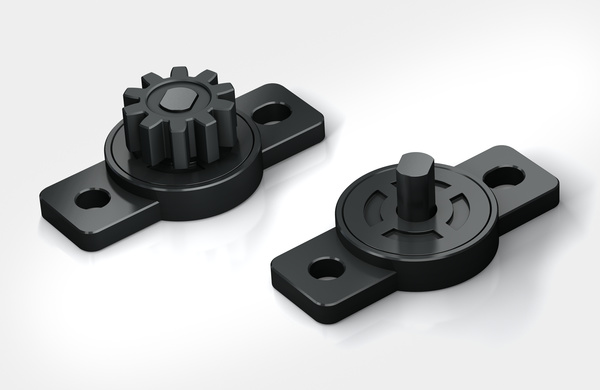

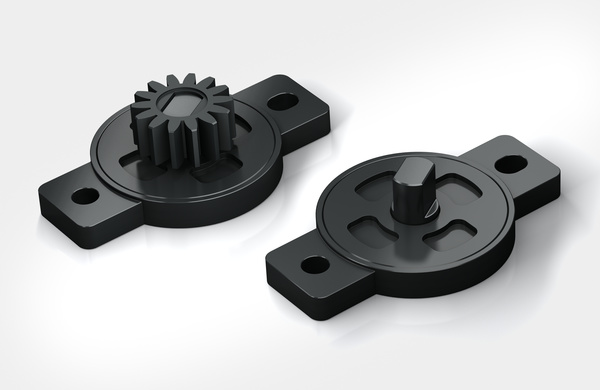

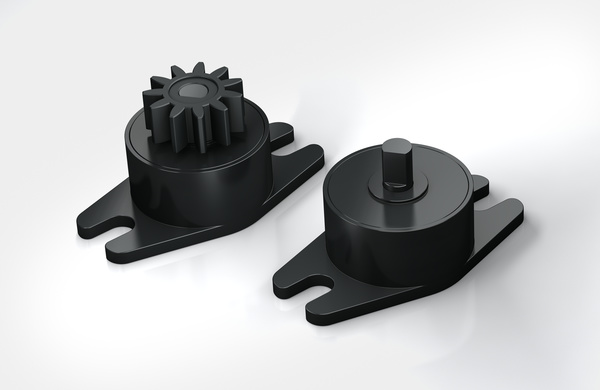

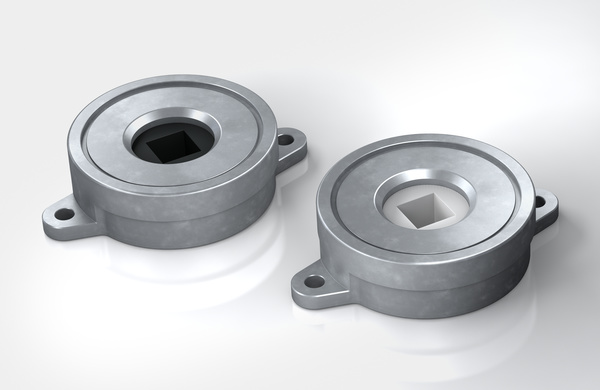

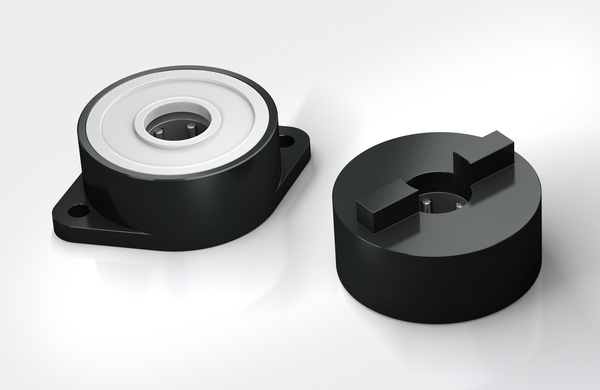

Rotary Dampers

ACE rotary dampers mainly provide an invisible yet valuable service as a maintenance-free machine element to allow controlled deceleration of rotary or linear movements.

They are often necessary to make careful opening and closing of small lids, compartments and drawers possible and they protect sensitive components while increasing the quality and value of products. They are easy to integrate. The harmoniously gentle movements of these little decelerators can be achieved with continual rotation or with limited pivoting angles. They slow down left, right or double sided rotation. Suitable for almost any application and currently also available in adjustable variations, they provide braking torques of 0.05 Ncm to 40 Nm.

FRT-F2/K2 and FRN-F2/K2

The damping direction of FRT F2/K2 and FRN-F2/K2 is either the right, left or two-sided rotation.

FYN-S1

The self-compensating FYN-S1 rotary damper with zinc die-cast body provides a constant sequence of movement for different masses.

FFD

In comparison to other rotary dampers, the ACE FFD product family does not need any fluid to generate the damping torque, but rather works on the principle of friction.

FYT-H1 and FYN-H1

The damping direction of the adjustable FYT-H1 and FYT-H1 can be right, left or two-sided rotation.

FDT

The damping direction of the flat constructive ACE rotary damper FDT with robust steel body is two-sided rotation.

FYT-LA3 and FYN-LA3

The damping direction of this adjustable high-performance rotary damper can be right, left or two-sided rotation.