ACE damping solutions convert kinetic energy into heat, improving machine speed, durability, and competitiveness. These machine elements smoothly decelerate moving loads and minimize strain, making ACE damping products highly valuable.

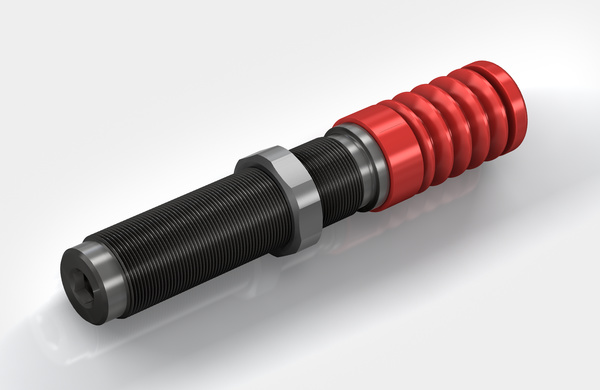

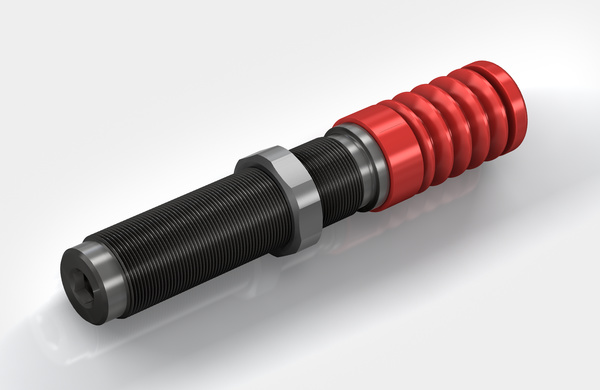

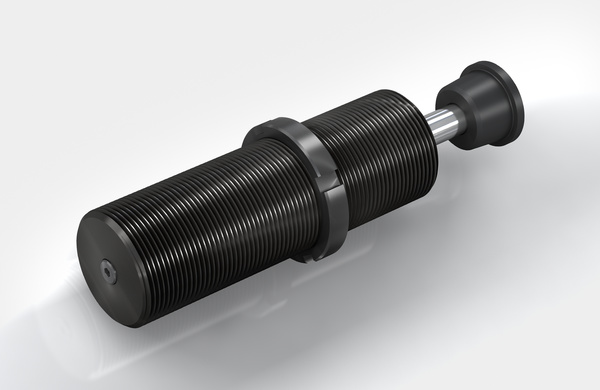

Miniature Shock Absorbers

Miniature shock absorbers from ACE are tried-and-tested quality products used in millions of industrial construction designs throughout the world. They optimise machines in an equally reliable and effective way by decelerating loads quickly and without recoil.

The compact, maintenance-free, hydraulic machine elements can be easily and quickly integrated in any construction design and certain models can be directly integrated in pneumatic cylinders. They reduce the load on handling devices, rotary and pivoting actuators, linear cylinders and many other industrial applications and increase their efficiency. Innovative ACE sealing techniques and shock absorber bodies and inner pressure chambers, fully machined from solid high tensile alloy, tube-shaped steel, ensure a long service life.

MC5 to MC75

Ideal for compact, efficient designs: The product family MC5 to MC75 impresses users with their reduced dimensions and their very short overall lengths and low resetting forces after braking.

SC190 to SC925

Ideal for soft damping: The SC found in the model code from the ACE product family SC190 to SC925 stands for ‘soft contact’.

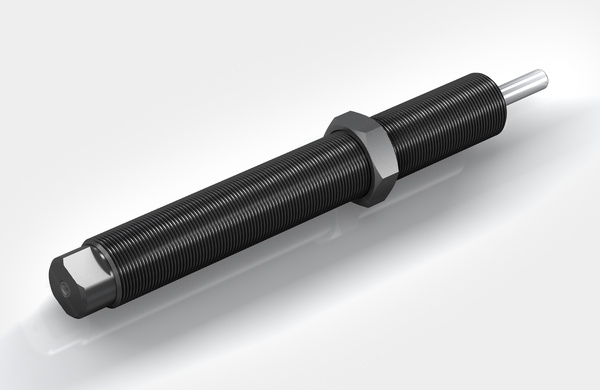

MC150 to MC600

Tried-and-tested and durable: Due to a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptional high lifetime of use with up to 25 million cycles.

SC²25 to SC²190

Soft damping, but enormous capacity: The range of ‘soft contact’ absorbers SC²25 to SC²190 extends from thread size M10 to M14 and covers effective weight ranges of 1 kg to 1,550 kg.

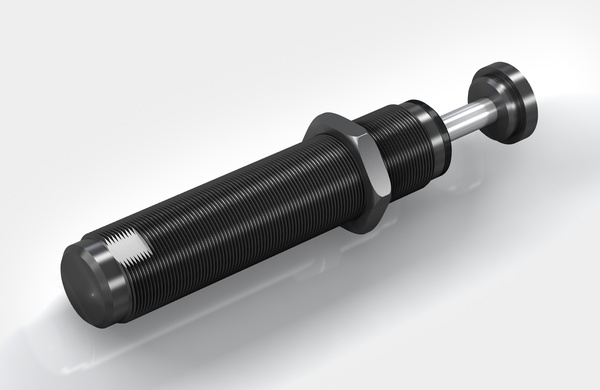

MC150-V4A to MC600-V4A

Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology.

SC²300 to SC²650

Added safety with accumulator technology: The larger ‘soft contact’ models from the SC²300 to SC²650 are available with up to three times the energy absorption compaired to similar sizes of standard shock absorbers SC190 to SC925, due to the ACE piston tube speciality.

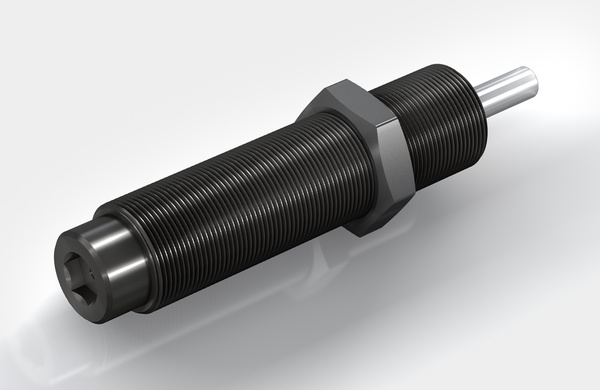

PMCN150 to PMCN600

Hermetically sealed: The shock absorbers from the ACE Protection family PMCN have a compact, perfectly sealed cap as a special feature.

MA30 to MA900

The miniature shock absorbers from the MA30 to MA900 product family can be adjusted and precisely adapted to your requirements

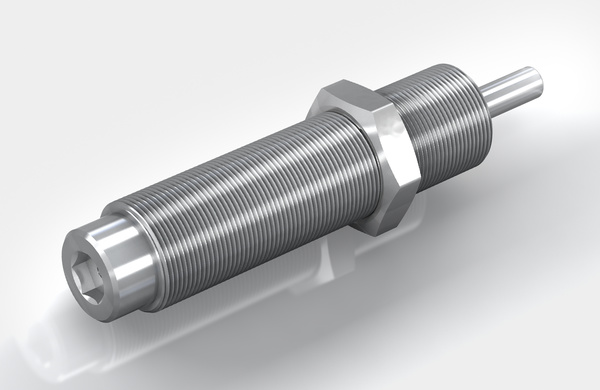

PMCN150-V4A to PMCN600-V4A

Hermetically sealed and rustproof: The Protection product family PMCN is also available in a stainless steel design.

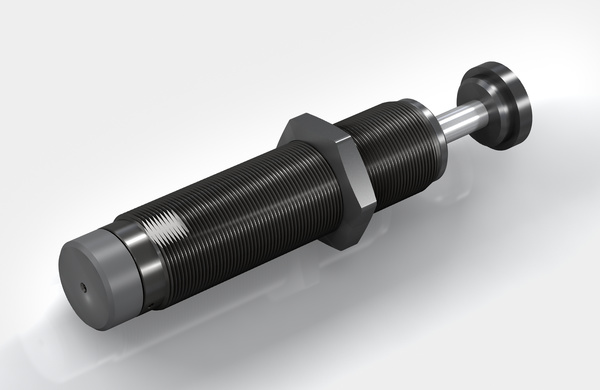

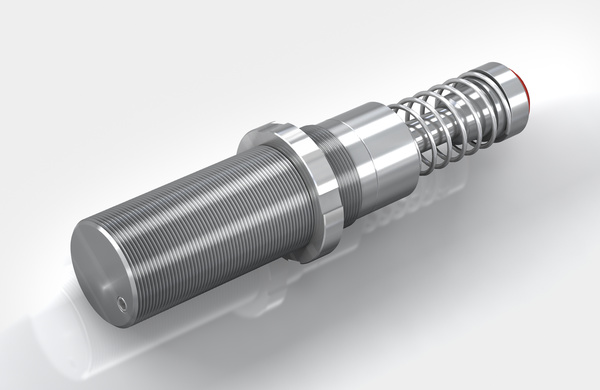

Industrial Shock Absorbers

ACE industrial shock absorbers work hard. Their application means moving loads are evenly decelerated over the full stroke. The result: the lowest braking force and shortest braking time. The MAGNUM series from ACE is viewed as the reference standard for medium design sizes in damping technology.

Innovations such as diaphragm accumulators, seals, tube-shaped inner pressure chambers and many more make a decisive contribution towards extension of the service life. This means that the effective load range can be extended considerably, which provides users with more scope with respect to the absorber size and utilisation of the machine’s output. ACE offers a wide range of matching accessories for this and all other absorber series. This eliminates internal production of assembly parts, which involves high costs and lots of time.

MC33 to MC64

The latest damper technology: The combination of the latest sealing technology, annealed guide bearing and integrated positiv stop make these self-compensating shock absorbers from ACE’S MAGNUM range so successful.

MC33-LT to MC64-LT

Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the LT (low temperature) industrial shock absorbers are also made from one solid piece.

MC33-V4A to MC64-V4A

The latest damper technology in stainless steel: The self-compensating industrial shock absorbers MC33 to MC64 from the tried-and-tested and popular MAGNUM range is also available with all outer components made from stainless steel, material 1.

SC33 to SC45

True performers: The combination of the proven sealing technology from the MAGNUM range including membrane accumulator with the well-known piston tube technology from the SC² family makes the SC33 to 45 absorber models so strong and durable.

MC33-HT to MC64-HT

Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece.

MA/ML33 to MA/ML64

Adjustable and unique: These industrial shock absorbers from ACE, which can be precisely adjusted both at the front and rear, also contribute towards the success of the MAGNUM range.

Heavy Industrial Shock Absorbers

The heavy industrial shock absorbers from ACE round off the top of the company”s offers in damping technology. Designers also have the choice between self-compensating and adjustable machine elements in this category from ACE.

Whichever design is chosen, this type of shock absorber impresses with its robustness and operational readiness wherever heavy loads need reliably stopped on-the-spot at a precise point.

The CA4 models can absorb up to 126,500 Nm of energy. The series of heavy duty, self-compensating CA types are equally suitable for use as an emergency stop as the adjustable types with the designations A1½ to A3. The range of effective loads covered is increased considerably for this purpose.

CA2 to CA4

Powerful: The mass of these high volume absorbers are between 12

A1 1/2 to A3

Strong and adjustable: Also in ACE’s range of units ares heavy duty industrial shock absorbers, which can be adjusted.

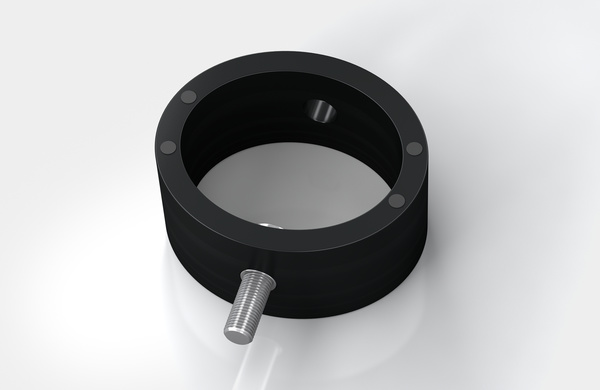

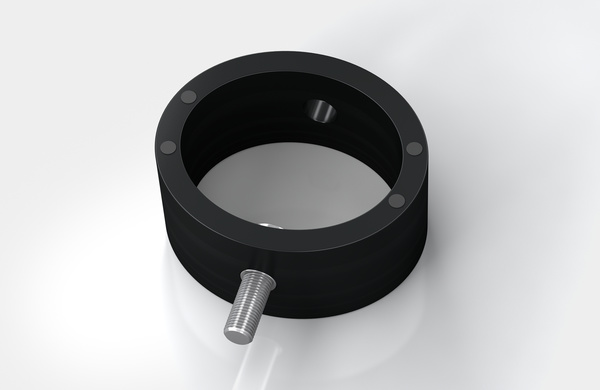

Profile Dampers

The exceedingly successful TUBUS series from ACE is a perfect alternative, when masses don’t need to be decelerated to an exact point. Available in more than 140 different versions, the profile dampers are used to slow down masses, particularly under extreme conditions.

They are also recommended for use if there is little installation space available. Manufactured in co-polyester elastomer, the highly resistant absorbers provide the best benefits in areas where other materials fail or where a similarly high service life of up to 1 million load changes cannot be achieved. They are affordable, compact and light and absorb the energy with different damping characteristics depending on the design.

TUBUS TA

Very efficient energy guzzlers: The TA profile dampers from the ACE TUBUS-Series are maintenance-free and ready to install.

TUBUS TR-H

Harder mixture of materials for higher energy absorption: The maintenance-free and ready-to-install TR-H profile dampers, are stressed radially in the same way as the basic TR model.

TUBUS TS

Energy absorption in a compact and uniform way: The TS (TUBUS soft) profile dampers are also manufactured from co-polyester elastomer.

TUBUS TR-H

Harder mixture of materials for higher energy absorption: The maintenance-free and ready-to-install TR-H profile dampers, are stressed radially in the same way as the basic TR model.

TUBUS TR

For long, soft braking action: The Radial damping forces in this model from the ACE TUBUS-Series provides the TR range.

TUBUS TR-HD

Impact and collision protection: The TR-HD profile dampers are stressed in the same way as the basic model TR but offer a higher force and energy absorption with a shorter damping distance thanks to the solid design.

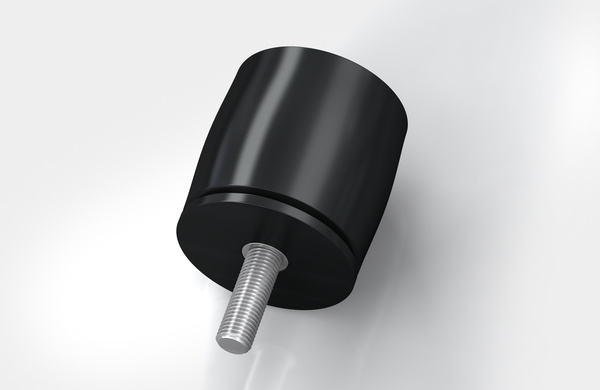

Damping Pads

With damping pads from the SLAB serices, ACE provides solutions to effectively slow down impact loads over large and small surfaces. This means that these products are found in a wide range of damping technologies from ACE where oscillation begins or where damaging impacts in construction designs need to be slowed over a large surface.

The ACE SLAB pads, available to choose in any size, absorb static loads from 3 to 30 N/cm² and can be either cut to size two-dimensionally according to each requirement or designed as a moulded part. It is simply adhered to assemble. The standard plate heights are between 12.5 and 25 mm. Many different coatings clear the way for numerous applications and not least because they can be used in a temperature range from -5 °C to +50 °C.

SLAB 030 to SLAB 300

Tailor made damping material in pad format: SLAB damping pads are made of a viscoelastic PUR-material